| Paraméter | Egység |

| Asztalméret | mm |

| Maximális munkadarb súly | kg |

| X tengely lökete | mm |

| Y tengely lökete | mm |

| Z tengely lökete | mm |

| W tengely löket | mm |

| Főorsó kúp | |

| Főorsó fordulat | ford/perc |

| Főorsó motor | kW |

| Vezérlés | |

| Géptömeg | kg |

HMC1000 HMC1200 HMC1600 1200x1000 3000 1500 1000 1200 600 BT-50 3500 22 Fanuc 18i-M 30000 1400x1200 5000 1800 1500 1500 700 BT-50 3500 22 Fanuc 18i-M 40000 1600x1600 8000 2200 1500 1500 700 BT-50 3500 30 Fanuc 18i-M 48000 HMC2000 HMC2500 2200x1800 10000 3200 1800 1500 700 BT-50 3500 30 Fanuc 18i-M 50000 2600x2200 15000 3400 1800 2000 700 BT-50 3500 30 Fanuc 18i-M 60000

Machine base

The symmetric box section of machine base is heat treated of properly stress released process, giving best stability and rigidity to allow the machine to extend its and provide mechanical features of heavy cutting capabilities.

High rigid spindle structure

The spindle is designed with high accuracy roller type bearings. This spindle design absorbs axial and radial loads, providing the best rigidity for a complete trouble free life.

Tool change system

The HMC series machines can be supplied with either 40 to 120 tool pocket High-Capacity Automatic Tool Magazines with bi-directional tool selection that shortens tool change time to effectively increase production efficiency.

Operation panel

This easy to use panel complies with all safety regulations. Alarm messages are in clear text. The graphics displays on the FANUC 18i-M is the best choice for machine operators.

High Precision Table Indexing System

The APC uses a system with 4 locator pins to ensure the pal¬let table is always clamped with high repeatability. Air blast is used to clean all 4 clamping surface contact areas.

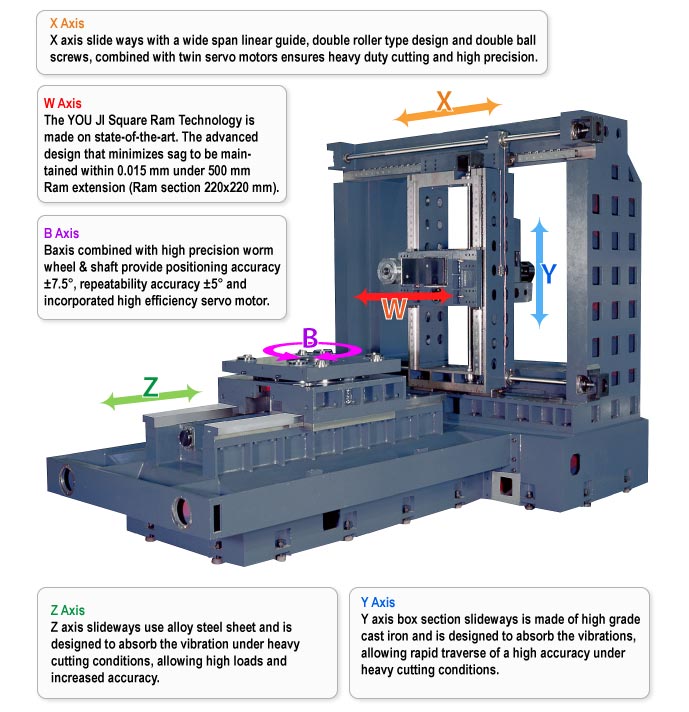

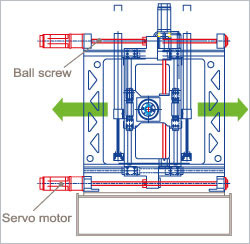

X-axis Twin Servo Drive

Compared against a single-drive system, HMC-series simultaneous twin servo drive for X-axis can increase the rapid traverse rate while ensuring vibration-free cutting conditions than otherwise possible. The balanced design also help minimize cutting vibration during Y-axis movement, so overall tool life is increased and machine precision is enhanced.

| Box-in-Box Design vs Conventional Single Column | |

HMC series Box-in-Box Construction is stable throughout | Conventional Single Column Design |

|  |

The bottom of the box-in-box construction does not move. The X-axis movement relies on a balanced design with slideways on both top and bottom of our Box-in-Box construction. The X-axis is driven with two ballscrews directly coupled to two FANUC servos simultaneously. The enhanced balance and extra rigidity ensure cutting accuracy under all conditions. |

Conventional single column slides on two guideways at the bottom. This design suffers from wobble at high speed. This unbalanced structure limits high speed movement and worse, it does not provide a rigid enough structure for heavy milling. |

Box-in-Box Construction Stands up to High Cutting Force | Single Column Suffers from Deflection |

|  |

High rigidity can achieved with this kind of design, avoiding deformation and machine resonance. This heavy duty Box in Box design increases heavy cutting by 15%. |

The weak design has a geometry problems, the cutting force can tilt the column back under cutting force. This will reduce accuracy and tool life. |